X

Pressure Die Casting Parts Price And Quantity

- 7000 INR/Unit

- 100 Unit

Pressure Die Casting Parts Product Specifications

- Powder Coated

Pressure Die Casting Parts Trade Information

- Cheque, Cash in Advance (CID)

- Days

- Yes

- Contact us for information regarding our sample policy

- Standard

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- All India

Product Description

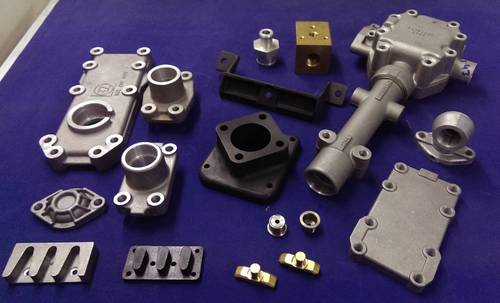

Backed by team of adroit professionals, we are offering a qualitative range of Pressure Die Casting Parts. These parts are used in the assembling of various vehicles. Our offered parts are precisely designed and manufactured using high quality raw material under the supervision of experts with advanced technology. These Pressure Die Casting Parts are available in various specifications according to need of the clients and at affordable prices.

Features:

-

Easy installation

-

Less maintenance

-

Sturdy construction

-

Durability

Pressure die casting produces intricate, high-volume metal components by injecting molten metal under high pressure into a reusable steel mold (die). These parts are characterized by their precise dimensions, smooth surface finishes, and ability to create complex shapes. Common materials include aluminum, zinc, and magnesium alloys, and the process is widely used in industries such as automotive, aerospace, and electronics for parts like engine components, electronics casings, and surgical tools.

Key Characteristics of Pressure Die Casting Parts-

The high-pressure injection ensures the molten metal fills the mold cavity completely, resulting in parts with high dimensional accuracy and close tolerances.

-

The process allows for the creation of intricate and complex part designs, including thin walls and detailed features, which are difficult to achieve with other methods.

-

It is an ideal process for the mass production of metal components, with a single die capable of producing thousands to millions of parts before needing replacement.

-

Pressure die-cast parts typically have a smooth, high-quality surface finish, reducing the need for extensive post-processing.

-

The ability to create thin-walled parts contributes to the production of lightweight components.

-

A wide range of metals, including various alloys of aluminum, zinc, copper, and magnesium, can be cast using this process.

Common Applications- Automotive: Engine blocks, transmission parts, housings.

- Aerospace: Components for aircraft.

- Electronics: Casings and housings for various electronic devices.

- Medical: Surgical instruments and other medical equipment.

- Consumer Goods: Plumbing fixtures and other household items.

-

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese